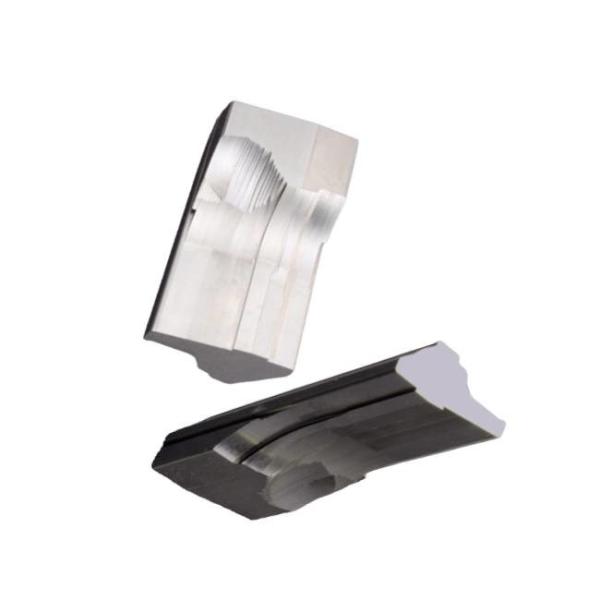

Customize Die Mold Components Mould Spare Parts Central Machinery

Parts

Die Mold Components Description:

Mold accessories refer to the general term for metal accessories

used in stamping molds, plastic molds, or FA automation equipment

exclusively in the mold industry. Die accessories include: punching

needle, punch, guide post, guide sleeve, thimble, cylinder, steel

ball sleeve, no oil guide sleeve, no oil slide plate, guide post

components, etc. The materials of mold parts are usually tungsten

steel, high-speed steel, bearing steel, stainless steel, brass,

metal alloy, spring steel, carbide steel and so on.

Plastic Injection Molds Parameter

| Company | Huishuo Co., Ltd |

| Business Type | Manufacturer and Exporter |

| Application | Auto, home appliances, electronics, medical, aviation,

communications, etc. |

| Products Name | Customized plastic injection mold and molding parts |

| Cavity | Single / Multiple Cavity |

| Shaping Mode | Plastic injection |

| Mold Base Material | LKM, FUTA, HASCO, DME etc. |

| Core & Cavity Material | Nak80, P20, H718, S136, SKD61, 2738, DC53, H13 etc. |

| Plastic Material | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS,

PEEK, HDPE, TPU, PET, PPO etc. |

| Other Materials | Rubber, silicone rubber, LSR, aluminum, zinc, copper, metal, etc. |

| Mould Life | 300,000 to 1,000,000 Shots (According to the working environment.) |

| Tolerance | 0.02mm -0.05mm |

| Runner | Hot runner, cold runner |

| Gate | Side gate, sub gate, pin point gate |

| Surface Finish | Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy |

| Plastic Injection Machine | 90T,138T,160T,168T,200T,260T,320T,400T,488T,600T,1000T |

Die Mold Components Specifications:

| Keywords | Die Mold Components |

| Place Of Origin | Dongguan China |

| Model Number | Customized |

| Product Material | Metal |

| Application | Machining |

| QC System | 100% Inspection Before Delivery |

| Delivery Time | 3-7days |

| Surface Treatment | Blacking/Chrome/Zincplating/DLC/TICN/Oxidation |

Wire EDM Technology For Die Mold Components:

Wire cut Electrical Discharge Machining (WEDM), sometimes called

wire cutting. Its basic working principle is to use a continuously

moving thin metal wire (called electrode wire) as an electrode to

perform pulse spark discharge on the workpiece to remove metal and

cut it into shape.

Wire EDM technology is a kind of special processing, which is

different from traditional processing technology, which requires

mechanical force and mechanical energy to cut, and mainly uses

electric energy to realize the processing of materials. Therefore,

WEDM technology is not limited by material properties, can process

any material with hardness, strength, and brittleness, and occupies

a critical position in machining at the current stage.

Die Mold Components Factory Introduction:

Huishuo Co., Ltd. is located in Dongguan City, China, and has been

committed to the design and manufacture of precision metal stamping

dies and injection molds since 2009, including metal stamping and

injection molding. In terms of progressive stamping dies, our

products mainly involve precision terminals, connectors, contacts,

clips, shrapnel, shells, shielding covers, etc. In metal stamping,

there are many precision presses with tonnage ranging from

25T-160T, all of which are gantry high-speed machines. It can

produce various coils and strips with a degree of 0.05-4.0mm. The

stamping materials include cold-rolled steel, stainless steel,

phosphor bronze, brass, red copper, beryllium copper, lead frame

materials, etc. Regarding plastic injection molding production, we

have many injection molding machines of various types between

50-160T, focusing on the production and processing of various

plastic products.