Shenzhen Huishuo Precision Technology Co., Ltd. is a

production-oriented enterprise with strong technical development

capabilities. Founded in 2009, it is located in Chang'an Town,

Dongguan, a major manufacturing town that enjoys the "Hometown of

Chinese Molds".

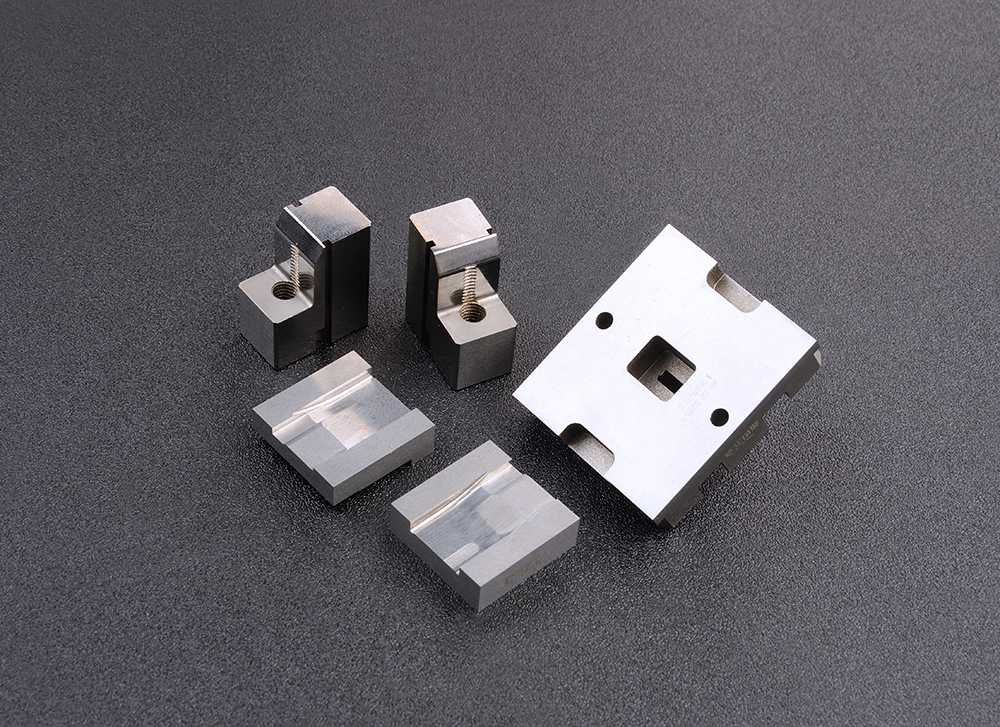

The company mainly focuses on the design and manufacture of precision sheet metal progressive stamping die, deep drawing

dies and plastic injection molds, production of metal stamping parts and plastic injection

products, etc. The stamping products and molds include precision terminals, connectors, shrapnel, shells, shielding covers, etc. The workshop area is about 5,000 square meters, with about

100 employees, a professional design, development, and processing

technical team, which can effectively ensure the delivery time and

quality of molds, products, and a professional quality management

team. Guaranteed customer needs.

The company adheres to the principle of "customer interests first",

and strictly controls the quality; it has advanced "Waida" and

"Wasino" optical curve grinding machines (P/G), Western Japan WEDM,

Japan Sodick WEDM and spark machines, small grinder, engraving

machine, fast wire, and a series of related auxiliary facilities,

as well as a series of advanced testing instruments, such as Nikon

projector, Ninkon altimeter, comparator, quadratic element, etc.,

can independently design and manufacture various high Difficult,

high quality and high stability metal stamping dies.

In terms of metal stamping products, there are many precision

punching machines with tonnage ranging from 25T-160T, all of which

are gantry high-speed machines. It can produce all kinds of coils

and strips with a degree of 0.05-4.0mm, and stamping materials

include cold-rolled steel, stainless steel, phosphor bronze, brass,

red copper, beryllium copper, and lead frame materials, etc.

In terms of plastic injection molding, we have multiple injection

molding machines ranging from 50-160T, focusing on the production

and processing of various types of connector plastic products.

We adhere to the business philosophy of "quality first, customer

first, forges ahead". After more than ten years of unremitting

efforts of all employees, we have won the high trust and support of

our customers, and have established good cooperation with many

well-known enterprises at home and abroad. relation. The products

sell well in mainland China, Hong Kong and Taiwan, Southeast Asia

and European and American markets. While continuously improving

production efficiency and product quality, the company also

continuously learns advanced enterprise management experience,

strengthens enterprise management, and improves the quality of

employees. The certification and implementation of the ISO9001:2008

international quality management system is a new starting point for

the company. We are convinced that through the company's continuous

improvement, continuous innovation and perfect service,

Huishuo Precision Mould will become a model in the mould

industry. Sincerely welcome people from all walks of life at home

and abroad to come to draw samples, discuss cooperation, enhance

friendship, and create a better tomorrow!